Resin Stone Surfacing

Modern, environmentally friendly and aesthetically impactful surfacing manufactured by Vuba Stone.

Proud partner of:

Why Choose Resin Stone?

Heavy Duty

Curb Appeal

Low Maintenance

About

In 2023, Vuba Stone partnered with Sierra Stone & Rubber Stone to bring Stone Resin Surfacing to North America.

Since 1988, Sierra Stone & Rubber Stone have worked with dealers across North America to transform surfaces, adding beautiful design elements to both residential and commercial spaces. During that time, they have built an extensive network of dealers to help customers achieve a space that is both stunning and functional.

Vuba Stone originated in the East Yorkshire town of Beverley in 2009, UK. Over the years, our Vuba Stone resin surfacing system has rapidly grown in popularity for residential homes as well as commercial spaces, leading us to expand into international markets to meet demand.

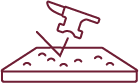

In the 70’s, polyurethane resin gained popularity as an industrial flooring system, replacing epoxy systems because of its durability, UV stability and flexibility. Throughout the 80’s and 90’s, this technology was translated into what would become the early systems of Polyurethane Resin Surfacing.

With Vuba Stone’s years of experience & technical knowledge and the Sierra Stone & Rubber Stone network of experienced installation professionals, we’re bringing you an exclusive resin-stone system that’s more durable, flexible, and UV stable than every epoxy-stone system on the market in North America.

Vuba Stone Binder UVR

System Guide

UV stable and hard-wearing, Vuba Stone surfaces do not discolor with time, and use different grades of aggregate sizes to increase their strength and longevity.

Benefits

100% Permeable

High Tensile

Prorated 5 Year Warranty

‘Extra Hard’ on the Shore Scale

Suitable for Vehicle Traffic

Excellent Elongation Strength

Authentic Exclusive Colors

Patented Binder

Applications

Venues & Stadiums

Housing Developments

Private Driveways

Public Buildings

Hospitality

Mixing and Application 5Search Vuba

Checklist Before Mixing

- Ensure each mix is set out in preparation next to the mixing area.

- Mark out the estimated coverage rate of each mix on to the surface.

- Ensure the resin tubs are unopened and the aggregate bags are dry.

Mixing Guidance:

1. Pour the Part B component into the Part A container, and mix using a drill and paddle for 90 seconds until a homogenous color is achieved.

2. Whilst the resin components are being mixed, add the 4 bags of aggregate to the rotating forced action mixer (22 gallon capacity) in order of largest rock to the smallest rock by diameter.

3. Once the rocks are added, pour in the resin mix and allow to rotate for a further 90 seconds. Taking care to ensure that all rocks are being fully encapsulated in resin.

4. After the resin has been added and begins to fold into the aggregate, add the Binding Quartz (for mixes to receive vehicle traffic only).

Application Guidance:

1. Spread the resin stone mix using a Notched Spazzle or Resin Bound Sledge. Set the aperture on your spreading apparatus to the required depth + 10% so that the additional 10% depth can be compacted into the resin system.

2. Once spread, compact at a 90° angle using a steel trowel (Resin Bull Ltd or similar) until the aggregated resin has been fully compacted and knitted into the preceding mix. Take care not to over-work the surface once approaching its gel time.

Further Information

To improve the slip resistance on the surface, crushed glass should be applied at a rate of 1/3 cup – 1/2 cup per 10 ft2.

For more application information ask us about our Resin Stone Training Course.

Coverage Rate

The Vuba Stone Resin Kit

USAGE

Pedestrian

Turning Vehicle

DEPTH

COVERAGE

Vuba 2k Polyurethane Vs Epoxy...

Why Polyurethane?

- High Chemical Resistance

- Excellent UV Stability

- Excellent Flexibility

- Capable of changing cure times on site (Catalyst)

- Crosslinking from exothermic reaction

Tensile Strength

Elongation to Break

UV Stability

UV Degradation

VUBA RESIN BINDER

High

>40%

Good

Low

EPOXY RESIN BINDER

26Mpa

1%

Poor

High

Vuba 2k Polyurethane Vs Epoxy...

Aftercare

Immediate Aftercare

- Curing Time

Do not walk on your new Vuba Stone surface for 24-48 hours, and do not drive on it for 48-72 hours after installation. These times are temperature dependent, and we recommend you always follow the installer’s advice for exact timings.

- No leaks/drips

Ensure there are no leaks or drips on the curing Vuba Stone. Excess moisture will significantly weaken and discolor Vuba Stone surfaces during the curing period. Continuous drips or leaks cause erosion in the long term, and will degrade the surface.

- Footprints

Ensure pesky people or animals cannot walk on the Vuba Stone surface. Footprints cannot be removed! Devices can be used to deter animals, and we would recommend to place tape or barriers around the perimeter.

5 Most Important Points to Remember

- Static wheel/small turning circles

Pressure exerted from static turning can dislodge surface aggregates. Once the matrix has broken, the surface will weaken and break away. It is very important that vehicle wheels are not turned when sitting still or slow moving, and small turning circles should be avoided.

- Impact Damage/High Point Loads

Take care not to drop heavy equipment on the driveway, such as the placement of disposal bins. Also be aware – disposal bins can often leach rust on to your driveway which you may not be able to clean. Car jacks can depress the surface of Resin Stone and should be placed on a wooden board for load distribution.

- Rejuvenating Your Surface

A great way to extend the life of your Vuba Stone surface is by sealing the surface with a diluted polyurethane UV resin sealer after a deep clean. Contact your Vuba Stone Dealer for more information.

- Chemicals and staining

Petrol, solvents, etc. should not come into contact with Vuba Stone surfacing ideally. In the event of spillages, dilute and clean immediately. Solvents and some chemicals will degrade the resin binder, resulting in stone loosening over a period of time.

- Leaching/Discoloration

Like all paving surfaces, Vuba Stone will discolor if covered long term with a close contact object. Discoloration occurs from leaching and lack of exposure to air and sunlight. Examples would be a flat bottom plant pot or a storage box. Avoid discoloration by using raised plant pots not using items like storage boxes on the surface.

Cleaning Advice

- Cleaning Practices

It is recommended to clean your Vuba Stone surface regularly. For lighter colors, it is even more important to carry out regular cleaning.

Vuba Stone surfaces can be power washed. It is recommended to hold the wand at a 90-degree angle and at least 6 inches from the surface. Cleaning too close may cause aggregates to be dislodged.

- Oil, Dirt & Debris

Oil, particularly lubricating or fuel oil, can easily penetrate into Vuba Stone surfacing but should not stain if spillages are removed immediately with an absorbent material. If the stain persists, an emulsifying degreaser should be employed.

Prolonged contact with any solvents should be avoided. For more information on cleaning, contact your Vuba Stone Dealer.

- Weeds, Moss & Algae

The application of a permeable membrane underneath the base will help to prevent weed growth from occurring. Absence of a membrane will result in weeds coming through the Vuba Stone. The Vuba Stone surface will not be able to prevent this. It is also possible for weeds to grow in the surface of Vuba Stone, but this can be easily pressure washed away.

Organic growth such as moss and algae may occur on hard surfaces where the area is heavily shaded or is under trees. If such growth does occur, the area should be treated with an appropriate cleaning solution according to manufacturers’ instructions.

- Fruit, Berries and Leaves

Fruit, berries and leaves can stain all types of paving surfaces. It is recommended to clean these away from the surface before they can begin to stain the Vuba Stone. Soiled areas may be cleaned with a mixture of liquid Sodium Hypochlorite (NaClO), obtained from swimming pool maintenance suppliers, and a non-oxidizing shampoo (E.g., Baby Shampoo).

Dilute 1.5 quarts of Sodium Hypochlorite with 4.5 quarts of water and add 3.5 ounces of baby shampoo. The mixture should be applied using a pump sprayer and the whole area treated, not just individual spots. First wet the whole area with clean water and then spray the cleaning fluid over the surface. Gently scrub the area with a stiff bristle brush. After 15 minutes, rinse the surface with clean water, making sure the residue does not run onto vegetation.

- Rusting & Tire Marks

Rust can occur from two sources. Typically, rust marks are caused by leaching from BBQ’s, flower baskets, and other metal garden items. Care should be taken to keep these from leaching on to the resin surface.

Naturally occurring aggregates in Vuba Stone may contain pyrite, which upon exposure to moisture can begin to rust. Unfortunately, this is an aspect of Vuba Stone surfacing which although very rare, can happen naturally.

Either cause of rusting can be cleaned using Non-Acidic Rust Stain Remover. Please follow manufacturer instructions.

Tire marks can normally be removed by scrubbing the area with detergent and hot water or steam cleaning.

We've got it covered

Read to see how Rubber Stone can make your space look, feel, and function better? Contact our design experts for a free consultation.